Laser Marking & Engraving

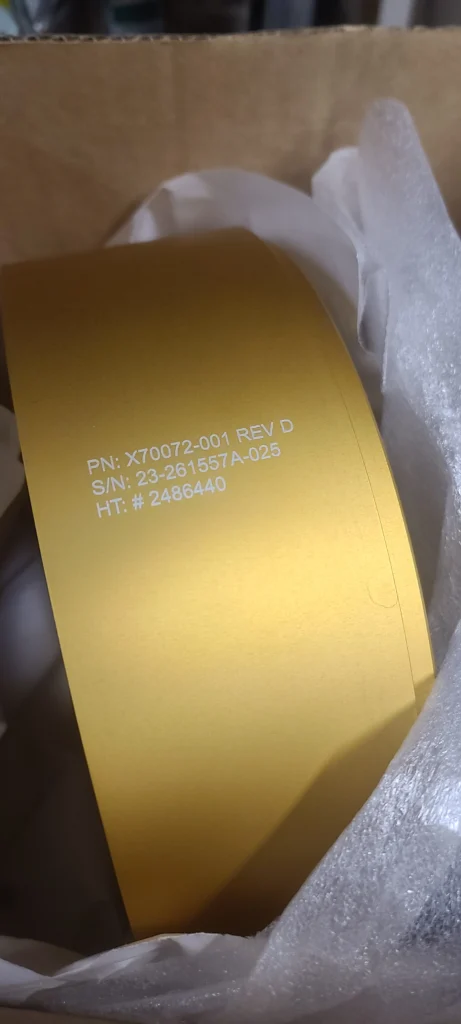

Fiber laser marking is a cutting-edge technology that uses a high-powered fiber laser to create precise, permanent markings on a variety of materials, including metals and plastics. With its non-contact process, it ensures no damage to delicate surfaces. Known for speed and precision, this versatile technology is ideal for applications in manufacturing, electronics, automotive, and more. It provides durable markings for product identification, branding, and traceability, making it an essential tool for modern industrial processes.

Materials

- Bare Metals

- Most Plastics

- Coated & Plated Metals

- Anodized

- Carbide

- Aluminum

- Ceramic

- Titanium

- Brass, Copper

Applications

- Curved Surface Marking

- Manufacturer Marking

- Logos

- Bar Codes/ QR Codes

- Text

- Industrial Parts Identification

- Serialization

- 3D Engraving

- Laser Cutting (up to .02″)

Laser Details

Pulse Precision currently employs the use of a 50W MOPA Fiber Laser for all of its marking, engraving and cutting. Our 1064nm wavelength laser head offers up to 97% transmittance with minimal distortion, and a working area of 7″x7″.